Waste Water Pump Stations

AGM Beton's pump stations are manufactured with the following diameters

Diameters

- DA 1000

- DA 1200

- DA 1400

- DA 1650

- DA 1800

- DA 2000

- DA 2200

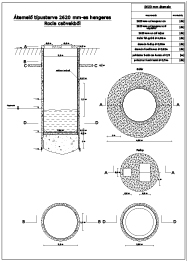

- DA 2320 (thin wall)

- DA 2620 (thin wall)

- DA 3060 (thin wall)

- DA 4640 (thin wall, a structure made of segments)

Gate chambers:

Available in the above sizes and with any servicable depth.

Building technology:

Servicable depth depends on the type of soil and the quantity of ground water. Pump stations are installed accordingly either with a trench (bottomed pipes) or a well-sinking technology. In the latter case dewatering is done by underwater concrete work.

Polibet shaft bottoms

Depending on the diameter, Polibet shafts can be delivered with two types of bottoms.

Standard polibet bottom

It is a plastic bottom for conventional pump feet. Available in designs as seen in the attached sample drawing.

Flygt TOP bottom

Flygt TOP bottom can be installed in conventional (non-polibet) shafts. Optionally the same geometry is available in reinforced concrete. In case of certain diameters (e.g. ND 2000) Flygt TOP bottom can also be installed in polibet shafts if the condition that the outer diameter of TOP bottom matches the inner diameter of the shaft is met, otherwise the plastic lining cannot be shut.

Engineering equipment in sewage pumps and plants

Any engineering configuration is possible. Basically, a twin-pump sewage plant contains the following items:

- pump feet, pipes, pipe brackets

- pipes (KO, or KG PVC)

- check-valves (one in each delivery side)

- gate valves (one in each delivery side)

- bifurcated pipes (to make common delivery pipes)

Various other purposes may be met by building in other engineering components, too:

- Pipe clamp + gate valve branched off the delivery pipe

- Induction meter

- Connectors, etc.